Manufacturing Cost: What Really Goes Into Making Your Medications

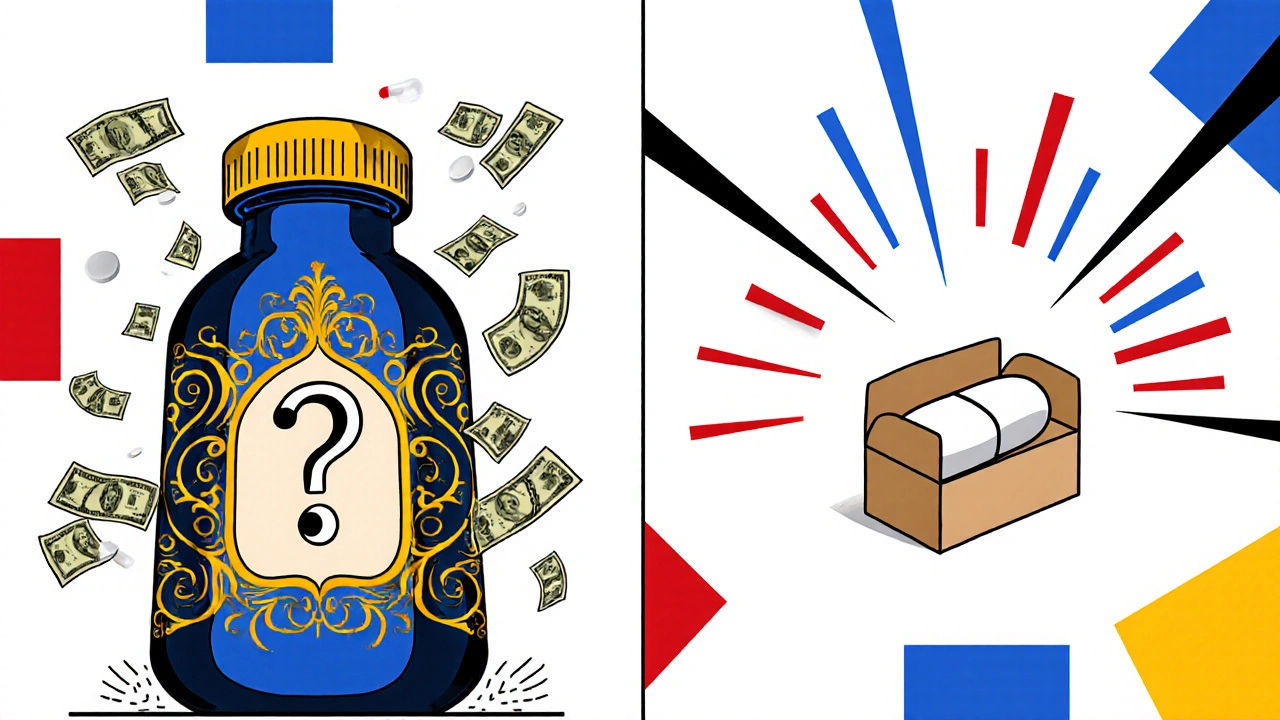

When you pick up a prescription, the price you pay doesn’t just reflect the active ingredient—it’s built on the manufacturing cost, the total expense of producing a drug from raw chemicals to sealed pill bottle. Also known as drug production cost, it includes everything from lab synthesis and quality control to packaging and compliance with FDA or Health Canada standards. Most people assume the cost is mostly the drug itself, but in reality, the active molecule might make up less than 5% of the final price. The rest? It’s the infrastructure, the testing, the paperwork, and the safety nets built into every batch.

Take a generic metformin pill. The chemical is simple, widely known, and cheap to make. But to sell it legally in the U.S. or Canada, the factory must prove every batch meets strict purity rules—each tablet tested for potency, dissolution rate, and contamination. That’s not a one-time check. It’s repeated across thousands of batches, year after year. And if you’re making a complex drug like dofetilide or sorafenib? The process gets even more expensive. These aren’t just mixed in a beaker—they’re synthesized in controlled, sterile environments with multi-step reactions, specialized equipment, and highly trained chemists watching every stage. Even small errors can ruin a whole run, and that loss gets baked into the final price.

Then there’s the hidden layer: regulatory compliance. Every drug manufacturer must follow cGMP—current Good Manufacturing Practices. That means clean rooms, calibrated machines, digital logs, employee training records, and audits. A single failed inspection can shut down production for months. That’s not a cost you see on the label, but it’s part of what makes your medicine safe. And when you compare branded drugs to generics, the difference isn’t always the active ingredient—it’s the brand’s investment in clinical trials, patent protection, and marketing. Generics skip those, but they still pay the full price of drug formulation, the science of turning a chemical into a stable, absorbable pill, liquid, or injection. Also known as pharmaceutical dosage form development, it’s what turns a powder into something your body can actually use. That’s why Neurobion Forte injections and Alfacip tablets cost more than plain B12 or vitamin D—they’re engineered for specific delivery, stability, and absorption.

Manufacturing cost also shifts depending on where it’s made. A pill made in India or China might be cheaper to produce, but shipping, import taxes, and local regulatory approvals add layers. And if you’re making a drug like spironolactone or cabergoline, which has strict controls because of side effects or misuse potential? Extra security, tracking, and documentation kick in—again, adding cost. Even something as simple as the color of a pill or the shape of a capsule can affect cost if it’s designed to help patients distinguish it from other meds, reduce confusion, or prevent counterfeiting.

That’s why you’ll see articles here about counterfeit medications, NDC numbers, and how to verify your drugs. Because when manufacturing cost is hidden, it’s easier for fakes to slip in. The same factory that makes safe, tested metformin can also make dangerous knockoffs—if no one’s watching. That’s why understanding manufacturing cost isn’t just about money. It’s about safety, trust, and knowing your medicine was made right.

Below, you’ll find real-world examples of how these costs play out—from the hidden expenses behind nerve injections to why some drugs cost more even when the active ingredient is identical. These aren’t theories. They’re facts pulled from how real medications are made, tested, and sold.

Manufacturing Cost Analysis: Why Generic Drugs Are So Much Cheaper

Nov 19 2025 / MedicationsGeneric drugs cost far less than brand-name versions because they skip expensive R&D, benefit from massive production scale, and face fierce competition. Learn how manufacturing efficiency drives down prices without sacrificing quality.

VIEW MORE